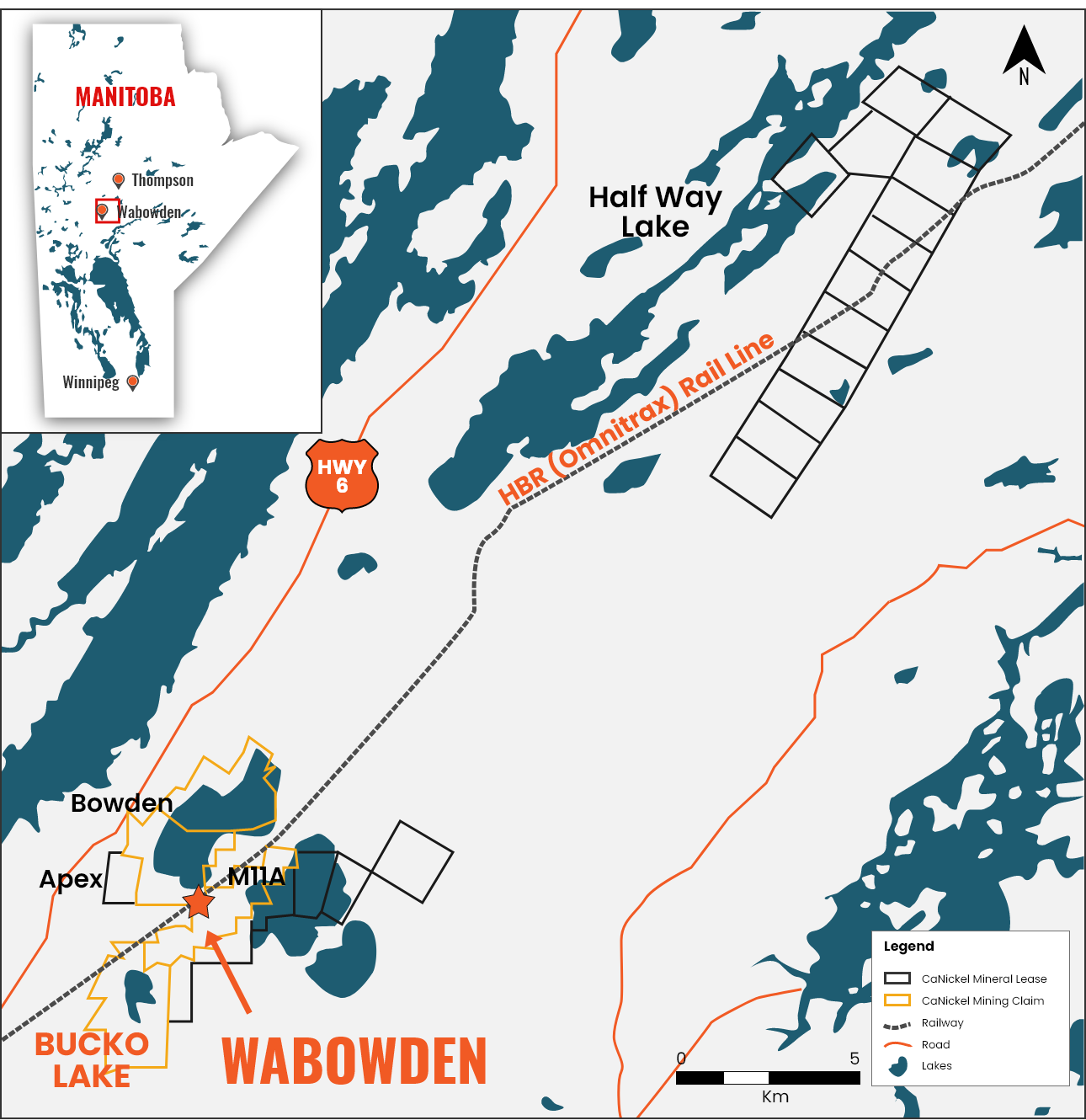

LOCATION

The Bucko Lake Mine is located just outside the town of Wabowden, Manitoba, 106 km south-southwest of Thompson and 640 km north of Winnipeg. Based on a 2021 census, the town of Wabowden has ~400 permanent residents with all necessary utilities, phone and internet service. There are no registered First Nations land claims affecting the project area.

The general terrain of the land is flat with outcrops of glacial rounded rock and wet muskeg lowlands separated by stands of fir and spruce trees. Ponds, swamps and shallow lakes are common. The Bucko Lake ore body is under the lake itself -- a small body of shallow water that does not exceed 2 m in depth. The lake does not have any cottages or inhabitants close by and is understood to be an area of little interest to the local population.

Access & Infrastructure

The Bucko Lake Mine is accessible from Provincial Highway 6 and a network of all-weather gravel roads and seasonal trails extending from the highway (built in 1977 and upgraded in 2008).

Surrounding infrastructure are associated with the town of Wabowden which is located centrally within the project area. The project area is transected by the HBR (Omnitrax) Rail Line to Churchill and a major hydro electric transmission line heading south along Hwy 6

Climate

The Bucko Lake Mine is an all-weather operation except for temporary unusual weather conditions. The winter affords increased access due to the frozen nature of surrounding wetlands.

The climate is typical of the Canadian shield with long winters and short warm to hot summers. Average temperatures range from a low average of -25°C in January to a high average of 17°C in July. The average number of frost-free days is 104. The annual precipitation averages 315 cm of rain and 147.5 cm of snow.

EXPLORATION & HISTORY

- Thompson Nickel Belt is discovered in Manitoba

- Marbenor Mines Limited acquires lands containing the Bucko Lake deposit

- Marbenor options the property to Falconbridge after drilling hole M77-B which intersected 1.54% Nickel over 6.3 m

- Bucko Lake mineralization is discovered after geophysical targets were drilled

- 53-hole program and over 21,000 m of work is completed

- An all-weather access road and a three-compartment shaft is developed by Falconbridge to 356 m below surface. Over 900 m of drift is developed on the 305 m (1,000 ft) level. A 61-hole, 12,000 m drill program is carried out

- Shaft is capped and allowed to flood; site demobilized

- Additional geophysical surveys are conducted and nine holes totaling 6,880 m of drilling is completed

- Nuinsco Resources Ltd. conducts DD drill program testing the continuity of mineralization and follows up in 2001 with 7,100 m of work

- Crowflight Minerals options project from Falconbridge and drills 77 holes totaling 32,246 m to infill areas of known mineralization, expand resources and reserves and to obtain bulk sample material for metallurgical testing

- Crowflight rehabilitates the former Falconbridge shaft, related facilities are built, and underground in-fill drilling is carried out to delineate mineral reserves and to increase the geotechnical database

- CaNickel releases updated mineral reserves and resources based on drill results obtained from surface and underground drilling completed from the 1960s to 2012

- CaNickel completes Winter drill program consisting of 8,683 m in 17 holes at the Bucko Lake North project area; 7,157 m in 12 holes at the M11A satellite deposit area; and 3,078 m in four holes at the Bowden Lake prospect

| Summary of Drilling – Bucko Lake and Satellite Properties – since the 1960s | ||||||

|---|---|---|---|---|---|---|

| Company Name | Year | Property | Metres Drilled | Number of holes | ||

| Crowflight | 2007-2008 | Halfway Lake | 5,734 | 13 | ||

| CaNickel/Crowflight | 2005-2012 | M11A | 27,743 | 63 | ||

| Crowflight | 2007-2008 | Apex | 4,263 | 13 | ||

| Falconbridge/Crowflight | 1960-2005 | Bowden Lake | 23,412 | 61 | ||

| Subtotal Satellite | 61,152 | 150 | ||||

| Crowflight | 1962-2008 | Bucko Lake | 101,174 | 340 | ||

| CaNickel/Crowflight | 2009-2012 | Bucko Lake | 42,471 | 285 | ||

| Subtotal Bucko | 143,645 | 625 | ||||

| Grand Total | 204,797 | 775 | ||||

MINERAL Resources

| Mineral Resource Estimate at Cut-off 0.70% Ni (1-6)* | ||||||

|---|---|---|---|---|---|---|

| Classification | Tonnes (k) | Ni (%) | Ni (Mlb) | Cu (%) | Cu (Mlb) | |

| Measured | 1,753 | 1.25 | 48.32 | 0.09 | 3.40 | |

| Indicated | 3,975 | 1.23 | 107.94 | 0.11 | 9.99 | |

| Meas + Ind | 5,727, | 1.24 | 156.26 | 0.11 | 13.39 | |

| Inferred | 10,587 | 1.18 | 275.59 | 0.13 | 31.15 | |

Notes:

- Mineral Resources which are not Mineral Reserves do not have demonstrated economic viability.

- The estimate of Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, socio-political, marketing, or other relevant issues.

- The Inferred Mineral Resource in this estimate has a lower level of confidence than that applied to an Indicated Mineral Resource and must not be converted to a Mineral Reserve. It is reasonably expected that the majority of the Inferred Mineral Resource could be upgraded to an Indicated Mineral Resource with continued exploration.

- The Mineral Resources in this report were estimated using the Canadian Institute of Mining, Metallurgy and Petroleum (CIM), CIM Standards on Mineral Resources and Reserves, Definitions (2014) and Best Practices Guidelines (2019) prepared by the CIM Standing Committee on Reserve Definitions and adopted by the CIM Council.

- Mined areas and barren pegmatite dykes were depleted from the estimate.

- The 0.70% Ni cut-off grade was based on an underground longhole method mining cost of $60/t, processing cost of $33/t, G&A cost of $12/t, Ni price of US$8.75/lb, 79% process recovery, 90% smelter payable, 16% mass pull, $276/t smelter treatment charge, $105/t concentrate freight cost, 2.5% NSR royalty, $1/t penalty charge and $3/t price participation cost.

*Source: Company PR from January 16, 2023

Development & Production History

- Crowflight completes initial feasibility report and undertakes work for full project permitting and additional resource definition drilling

- Construction begins with foundation work in support of infrastructure to dewater and rehabilitate the historical three-compartment, 330-metre-deep shaft

- Crowflight releases updated BFS

- Construction of the mill building, de-watering and rehabilitating the shaft to the 1,000-foot level is complete

- Crowflight receives license from the province of Manitoba to commence production at Bucko

- Commissioning of mill and first production of nickel concentrate

- First concentrate is shipped to Xstrata Nickel’s smelter in Sudbury

- Operations are suspended so company can bring in its own underground mining equipment and team and to make operational adjustments

- Mining and milling operations resume; Crowflight reorganized and renamed to CaNickel Mining Limited

- CaNickel granted a revised Environment Act License to construct and operate a land-based tailing management area at Bucko Lake

- Reduction of operations due to low nickel prices

- CaNickel attempts combination of cut and fill mining and long-hole stoping mining methods

- CaNickel attempts combination of cut and fill mining and long-hole stoping mining methods

- Operations ramped up to full capacity

- Completion of Phase 1 of tailings management area

- CaNickel suspends mill operations due to lower nickel prices and higher mining costs for cut-and-fill mining methods

- Bucko Lake Mine under Care & Maintenance

Bucko Lake Mine now – Under Care & Maintenance

Headframe Construction (2008)

Construction of Mill Building (2008)

Construction of Mill Building (2008)

Concentrate Shipment (2009)

Production History

| BuckoLake Mine Production History | ||||||

|---|---|---|---|---|---|---|

| Year | Ores Mined (tonnes) | Ores Milled (tonnes) | Head Grade | Mill Recovery Rate | Nickel Produced | Nickel Payable Sold |

| 2009 | 135,931 | 124,970 | 1.00% | 55.52% | 1,382,606 | 1,152,697 |

| 2010 | 131,884 | 131,884 | 1.23% | 69.00% | 2,476,116 | 2,125,202 |

| 2011 | 107,451 | 102,069 | 1.18% | 61.00% | 1,631,916 | 1,363,534 |

| 2012 | 72,256 | 76,650 | 1.12% | 75.65% | 1,437,510 | 1,445,523 |

| Total | 447,522 | 435,573 | 6,928,148 | 6,086,956 | ||

Offtake Agreement & NSR

All nickel concentrate produced from the Bucko Lake Mine is shipped to Glencore’s Sudbury, Ontario smelter under payment terms specified in an offtake agreement. These terms are subject to fluctuations in the spot market price for nickel.

Under the terms of the Agreement, a 2.5% net smelter return (NSR) is payable to Glencore on the proceeds of production for all nickel sold at a monthly average daily spot price that is greater than US$6.00 per pound of nickel. The NSR is not payable for product sold at a metal price less than US$6.00 per pound of nickel.

Geology &

Mineralization

The Bucko Lake Property is located within the Thompson Nickel Belt, a northeastern trending zone several kilometres wide and 100 km long of variably reworked Archean basement gneisses and early Proterozoic cover rocks between the superior and Churchill Provinces in northern Manitoba. This zone has a distinctive gravity and magnetic geophysical signature.

The property itself is underlain by Archean gneisses and Proterozoic ultramafic intrusive rocks. The gneisses have been intruded by Aphebian ultramafic sills including the Bucko Lake Ultramafic which hosts the nickel mineralization on the property.

The nickel deposits are genetically and spatially related to serpentine sills. Their present distribution is the result of re-mobilization during the long and complex tectonic history of the Thompson Belt.

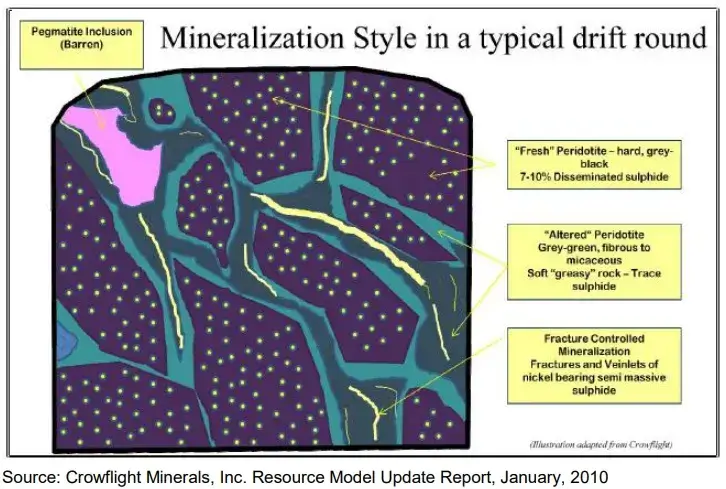

Nickel sulfide mineralization consists of disseminated to net textured nickel sulfides ranging in concentration from 1-50% by volume which are locally remobilized along fractures within the ultramafic intrusion and along contacts with pegmatite and gneiss. Broad zones of disseminated lower grade mineralization (>1.0% nickel) typically envelope higher grade net textured to semi-massive sulfide layers or shoots (>3% nickel) within segregated portions of the ultramafic intrusion. Mineralization consists of disseminated to net textured sulfides containing (in order of relative abundance) pentlandite, pyrrhotite, mackinawite, pyrite, and chalcopyrite.

Three areas of nickel mineralization are currently recognized within the Bucko Lake deposit:

(1) The West Limb or western limb of the structure. The Lower, Middle, and Upper Zones follow interpreted continuity in elevated mineralization between drill intercepts through corresponding portions of the intrusion. Two corridors of elevated nickel within this area are referred to as the North and South trends.

(2) The Hinge Zone occupies the “hinge” area between the western and eastern fold limbs and represents the northernmost portion of the deposit and consists of three zones of mineralization interpreted to be folded extensions to the Lower, Middle, and Upper Zones observed on the West Limb.

(3) The Footwall Zone represents a new mineralized horizon that was intersected during the course of infill drilling and driving footwall development on the 1,000-ft (308.4 m) level in 2008. This zone is interpreted to have ties within mineralization intersected by historical exploration drill holes near the southern limit of drilling on the 1,400 foot (426.7 m) level.

A network of remobilized sulfide veinlets ranging from the millimetre to several metre scale are associated with a fracture controlled talc/tremolite/phlogopite/anthophyllite alteration network that overprints the intrusion. Sulfides are also observed along altered contacts with pegmatite dykes cross-cutting the intrusion.